3D Printing Phoenix accelerates industrial product development and improves design accuracy. Finding and fixing problems early in the process also reduces the risk of costly revisions and tooling changes.

Several different printing methods exist, including sintering, melting, and stereolithography. The right choice depends on the specific needs of the application.

3D Printing is a cost-effective method of manufacturing. It eliminates the need for multiple design phases and can reduce per-unit costs. In addition, the process avoids the costly tooling and per-unit material costs associated with traditional manufacturing methods. This means you can bring your product to market faster and without a significant amount of investment.

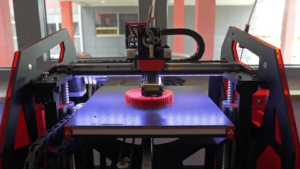

The first step in the 3D printing process is to create a virtual design of the object you want to make using computer-aided design (CAD) software. This will work as a blueprint for the printer, and is then sliced into layers. The layer-by-layer printing process ensures that only the necessary amount of materials is used, reducing wasted materials. This also allows for complex designs that would be impossible to produce with traditional technology.

Another way 3D Printing is cost-effective is by eliminating assembly time and reducing maintenance costs. In addition, it can be used to create composite parts that combine several components into one. This can result in increased performance, lower inventory costs, and reduced shipping costs. 3D Printing can also help reduce the cost of raw materials by utilizing waste concrete from construction sites. This reduces the need for formwork, which is a temporary structure that holds wet concrete in place while it hardens.

One of the biggest challenges with 3D Printing is predicting operational costs. A number of factors can influence the overall print cost, including the complexity and size of the printed object, print time, and energy consumption. For accurate cost forecasting, use a 3D printing cost calculator that takes into account these factors to provide a more realistic estimate of the total project cost.

Labor costs can be a major contributor to the overall cost of 3D Printing, especially in professional or commercial environments. This is because skilled operators are required to operate the equipment, perform post-processing, and maintain quality control. However, the use of automated calibration and self-calibration features can greatly reduce labor costs and improve print consistency.

Another way to lower 3D printing costs is by bringing production capabilities in-house. This can reduce the risk of intellectual property theft, as well as cut logistical costs by avoiding import taxes on finished goods. It can also improve customer response times by allowing companies to manufacture products on-demand.

Rapid prototyping

When developing a new product, it’s important to test your ideas as quickly as possible. This is where rapid prototyping comes in. Traditional production methods can take weeks to get a prototype in your hands, but with 3D Printing, the process is much faster. It takes just hours to make a part, and you can use different materials to test how the part will perform. This allows you to change and iterate on your design, which helps reduce costs and time to market.

This technology has many uses, from mechanical components and architectural models to intricate jewelry designs and consumer goods. The ability to print quickly enables companies to perform a proof-of-concept prototype before beginning full-scale production, reducing the risk of costly mistakes and accelerating time to market. It’s also used for on-demand manufacturing, which cuts down the need to keep a large inventory in stock and makes the process more efficient.

3D Printing is a one-step process, which saves time and money by eliminating the need for multiple machines. It also produces little to no waste, which is a big advantage over conventional manufacturing processes. Another benefit of 3D Printing is that it’s a highly customizable process, which enables you to create a model with the exact features you need. This enables you to design more complex products and reduce the amount of machining time needed for assembly.

The first step in 3D Printing is creating a virtual design. This is done using computer-aided design (CAD) software, a type of program that can create precise drawings and technical illustrations. The CAD file is then broken down into layers that the printer can process, one layer at a time. The layers are then deposited on the build platform by the machine.

A wide variety of materials can be used in 3D Printing, including polymers, composites, and industrial metals. Some 3D printers can even produce parts with a high degree of accuracy, which is essential for prototyping complex mechanical components. Moreover, some 3D printing techniques can remove material from existing parts, making them lighter and more cost-effective.

Confirmation of design

Throughout the world and even in space, people use 3D printers to create tools, clothes, food, art, organs, buildings, and jewelry. The technology is a revolutionary invention that has revolutionized many aspects of the economy, and it continues to push the boundaries of what can be made with it.

However, a number of challenges remain. These challenges include the lack of a standard method for drafting engineering drawings that serve as clear manufacturing blueprints or inspection checklists. Additionally, the lack of a common design language leaves room for information about 3D-printing designs to be lost in translation. These issues can make it challenging for engineers to produce quality printed parts and to ensure the safety of those parts.

3D Printing is a relatively new technology that uses additive manufacturing to create a physical object from a digital model. It has become a popular tool for manufacturers, engineers, designers, educators, medics, and hobbyists. Some of the most interesting applications for this technology are in medicine and space exploration. For example, Walter Reed Army Medical Center is using 3D Printing to create cranial implants that are customized for each patient. These implants are made out of titanium, and they are designed to fit the exact shape of the patient’s skull. In addition, scientists have experimented with printing skin or heart cells that could be used for transplants.

The 3D-printing process requires a high degree of control, so it is important to have the right software and hardware. The CAD (Computer Aided Design) software that comes with 3D printers allows you to create and manipulate your model, which is then sent to the print head to produce the final product. You can also purchase additional CAD software that will allow you to create more complex models.

Another important consideration is that some types of parts require a more specialized design for the additive printing process. These parts may need to have internal passageways, be able to bend and curve or have other features that are not easily achievable with traditional subtractive machining processes. For this reason, it is important to always consider the printing process when designing a part.

Customization

3D Printing has become one of the most versatile production technologies, allowing manufacturers to produce a variety of parts and products on demand. The technology eliminates the need for costly tooling and molding, and it allows designers to implement rapid design changes. Moreover, 3D Printing is a great solution for small-volume production runs, reducing storage costs and the need for large inventories. This makes it an ideal technology for the consumer goods sector, where brands must respond quickly to changes in market demand.

In addition to design flexibility, 3D Printing enables precise customization tailored to each individual customer. Customization can include dimensions, materials, and functionalities, enabling manufacturers to meet customers’ needs in ways they never could before. It also enables them to optimize performance and create ergonomic fit. These advantages help them to stay competitive in a rapidly changing marketplace.

Although the customization capabilities of 3D Printing are impressive, this process is not without its limitations. For example, certain geometries and intricate details may not be possible, depending on the size of the print chamber and the type of materials used. This can affect the quality of the finished product. Additionally, 3D Printing requires a lot of attention and care to get the best results. This is because 3D printers produce a high volume of heat, which can cause burns and other injuries. In order to avoid these risks, it is important to use proper protective gear and work in a well-ventilated area.

Despite these limitations, the customization capabilities of 3D Printing are revolutionizing the world of manufacturing. The technology is now widely adopted by a wide range of industries, including aerospace, medical, automotive, and fashion. These industries are using 3D Printing to create everything from prototypes to final parts and products. For example, NASA has used 3D Printing to produce prosthetics for its astronauts, while Walter Reed Army Medical Center has printed titanium cranial implants customized to each patient’s injury.

To achieve the highest-quality prints, it is important to choose the right design software for your project. There are many options available, from expensive commercial software packages to free and open-source programs like Blender. However, before you buy any software, make sure it works with your 3D printer and offers the features you need. It is also important to consider the support options and online community of your chosen program. Guided tools and detailed tutorials are often helpful for beginners, while a strong online community provides valuable assistance to troubleshoot problems.